In the world of CNC machining, G-code plays a crucial role in controlling and guiding the movement of machines. Understanding G-code is essential for anyone working with CNC machines, whether you’re programming, operating, or troubleshooting. This comprehensive guide will explore what G-code is, how to read it, and cover some of the most common G-code commands you need to know to enhance your workflow. Let’s dive in!

Table of Contents

What is G-code?

G-code, also known as General Code or Programming Code, is a language used to control CNC machines. It is the set of instructions that tells a CNC machine how to move, what speed to use, and what path to follow. G-code controls everything from the machine’s movements to the way tools interact with the material. CNC machines rely on this language to execute tasks such as milling, drilling, and 3D printing.

Think of G-code as a set of detailed instructions, written in a language that the machine can understand, to automate manufacturing processes. By inputting these commands, a machine operator can ensure high levels of accuracy and precision when producing complex parts or products.

Why is G-code Important for CNC Machines?

G-code is the backbone of CNC machining. Without it, CNC machines would not function. It allows operators to create intricate designs and achieve precise cuts, which are essential for industries like aerospace, automotive, and manufacturing. By mastering G-code, you can unlock the full potential of your CNC machine and improve your productivity.

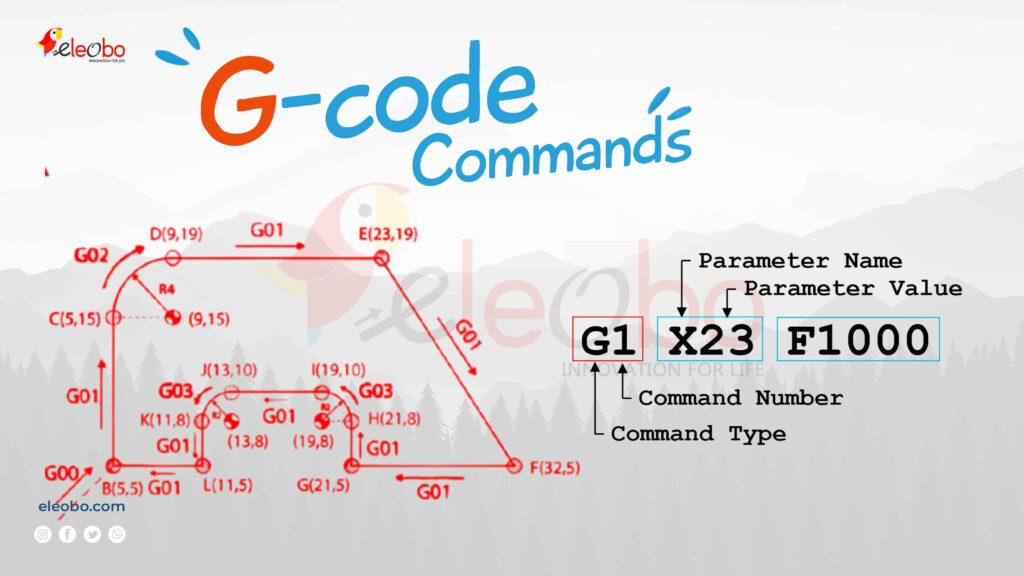

How to Read G-code Commands

Reading G-code commands is not as difficult as it seems. G-code commands are typically made up of a combination of letters, numbers, and sometimes a decimal point. Each letter represents a specific action or command, and the numbers define the values or parameters associated with that action.

For example:

- G00: Rapid positioning

- G01: Linear interpolation (move in a straight line)

- X, Y, Z: Coordinates of the machine tool

- F: Feed rate (speed)

Each command is followed by the specific numbers or values that define its action. For example, G01 X5 Y10 F200 tells the CNC machine to move in a straight line (G01) to the coordinates X5 and Y10, with a feed rate of 200.

It’s important to note that G-codes may vary slightly depending on the specific CNC machine or controller you are using, but the general syntax remains the same.

The Most Important G-code Commands

While there are many G-codes available, there are a few that are used more frequently in CNC programming. Let’s go through some of the most important G-codes you will encounter.

G00 – Rapid Positioning

G00 is used for rapid positioning. When you input this code, the machine moves as quickly as possible to a specific location without regard to the path. It’s typically used when moving the tool or machine part to a position before beginning the cutting process.

Example:

- G00 X10 Y10 tells the machine to move quickly to the X10, Y10 position.

G01 – Linear Interpolation

G01 is used for linear interpolation, or a controlled straight-line movement. When this code is used, the machine will move to the specified position at a defined feed rate.

Example:

- G01 X50 Y50 F200 tells the machine to move to the X50, Y50 position in a straight line at a feed rate of 200.

G02 – Circular Interpolation Clockwise

G02 is used for circular interpolation in a clockwise direction. This command helps the CNC machine move in a circular arc in a clockwise direction to a target location.

Example:

- G02 X50 Y50 I25 J25 tells the machine to move to the X50, Y50 position in a clockwise circular arc with a center offset of I25, J25.

G03 – Circular Interpolation Counterclockwise

G03 is used for circular interpolation in a counterclockwise direction. It’s similar to G02 but moves in the opposite direction.

Example:

- G03 X50 Y50 I25 J25 tells the machine to move to the X50, Y50 position in a counterclockwise circular arc with a center offset of I25, J25.

G20/G21 – Units Selection

G20 and G21 are used to select the units of measurement for the program. G20 sets the units to inches, while G21 sets the units to millimeters. This ensures that all coordinates and movements are interpreted correctly.

Example:

- G20 sets the machine to work in inches.

- G21 sets the machine to work in millimeters.

G17/G18/G19 – Plane Selection

G17, G18, and G19 are used to select the active plane in CNC programming. G17 selects the XY-plane, G18 selects the XZ-plane, and G19 selects the YZ-plane. The machine tool will operate in the selected plane when these codes are used.

Example:

- G17 sets the machine to work in the XY-plane.

G28 – Return Home

G28 is used to return the machine to its home position. This command is especially useful when you need to reset or stop the machine, and it ensures that the tool returns to its original starting position.

Example:

- G28 tells the machine to return to the home position.

G90/G91 – Positioning G-code Commands

G90 and G91 are used to define the mode of positioning.

- G90: Absolute positioning, where all coordinates are referenced from the machine’s origin.

- G91: Incremental positioning, where all coordinates are referenced from the current position.

Example:

- G90 sets absolute positioning mode.

- G91 sets incremental positioning mode.

More G-code Commands and Rules

Beyond the basic commands, there are other G-codes you will use in CNC programming. These include commands for spindle control, coolant control, tool changes, and more. Some of these may depend on the type of machine or CNC controller being used.

- M03 – Spindle on clockwise

- M04 – Spindle on counterclockwise

- M05 – Spindle stop

- M08 – Coolant on

- M09 – Coolant off

It’s important to familiarize yourself with the G-code manual of the specific machine you’re using, as different machines may support different codes.

Simple G-code Program Example

Let’s put all this into action by creating a simple G code program. This program will move the machine’s tool to specific positions using some of the G-codes discussed above.

G21 ; Set units to millimeters

G90 ; Absolute positioning

G00 X0 Y0 ; Move to the origin (0,0)

G01 X50 Y50 F100 ; Move to X50 Y50 at a feed rate of 100

G02 X100 Y100 I25 J25 ; Circular move clockwise

G03 X50 Y150 I25 J25 ; Circular move counterclockwise

G28 ; Return home In this program:

- The machine is set to work in millimeters (G21).

- G90 is used to set absolute positioning.

- The machine first moves to the origin (G00 X0 Y0).

- Then, it moves in a straight line to X50 Y50 (G01 X50 Y50 F100).

- Circular moves are performed using G02 and G03.

- Finally, the machine returns to its home position using G28.

Tips for Writing Effective G-code

- Plan Your Design: Before writing G code, plan your design and toolpath carefully. This will help you avoid errors and ensure smooth operation.

- Use Comments: Add comments to your G code program to make it easier to understand and troubleshoot.

- Test Your Code: Always test your G code on a simulator or in a safe environment before running it on the actual machine.

- Stay Organized: Keep your G code programs organized and well-documented for future reference.

Conclusion

G-code is a powerful language that gives CNC machines the ability to execute complex tasks with high precision. By understanding G code, you can significantly improve your CNC machining efficiency and accuracy. Whether you’re working on a simple project or a complex design, mastering the most common G-codes like G00, G01, G02, and G03 is a must. Always ensure to read and interpret G-code commands carefully, as even a small mistake can result in errors or inaccuracies in the machining process.

With practice, you’ll become more confident in writing and reading G-code, ensuring your CNC operations run smoothly. Stay updated on the latest G-code developments and keep honing your skills. Happy machining!

By understanding these essential G codes, you’re well on your way to mastering CNC machine programming. Start experimenting with different commands and see how they affect the movement of your machine.

Here are some commonly asked questions about G-code with answers:

General Questions About G-code

1. What is G-code, and why is it important in CNC machining?

G-code is a programming language used to control CNC (Computer Numerical Control) machines. It consists of commands that tell the machine how to move, cut, or shape materials like metal, wood, and plastic.

2. How does G Code work in a CNC machine?

G-code provides step-by-step instructions for a CNC machine, such as moving the tool, setting spindle speed, and controlling coolant. The machine reads these commands and executes the programmed movements.

3. Is G-code the same for all CNC machines?

No, while the basic structure of G code is similar, different CNC machines (like Fanuc, Haas, and Siemens) may have variations in commands and syntax.

4. What are the basic G Code commands every beginner should know?

Some essential G code commands include:

G00– Rapid positioningG01– Linear feed motionG02/G03– Circular interpolation (clockwise/counterclockwise)G90/G91– Absolute and relative positioningM03/M05– Spindle start/stop

5. Can I edit G code manually, or do I need special software?

You can edit G code manually using a text editor, but it is easier to use CAM (Computer-Aided Manufacturing) software like Fusion 360, Mach3, or GRBL.

Reading and Writing G-code

6. How do I read and understand G code commands?

Each G-code line consists of a letter (G, M, X, Y, Z, F, etc.) followed by numbers that define movements, speed, or other actions. Example:G01 X100 Y50 F300 – Moves the tool to (X=100, Y=50) at a feed rate of 300.

7. What do the letters and numbers in G code mean?

G– General machine movements (e.g., G00 for rapid move)M– Miscellaneous functions (e.g., M03 for spindle ON)X, Y, Z– Coordinates for tool movementF– Feed rate (speed of tool movement)S– Spindle speed

8. How do I write a simple G code program?

A basic program for milling a square:

G21 (Set units to mm)

G90 (Absolute positioning)

G00 X0 Y0 Z5 (Move to start position)

G01 X50 Y0 F300 (Move to X=50)

G01 X50 Y50 (Move to Y=50)

G01 X0 Y50 (Move to X=0)

G01 X0 Y0 (Return to start)

M30 (End program)9. What software can I use to generate G code?

You can use Fusion 360, Easel, Cura (for 3D printing), or GRBL-based software to generate G-code.

10. How do I convert a CAD file into G code?

You need CAM software (like Fusion 360 or Mastercam) to process a CAD file (.DXF, .STL) and generate G-code instructions.

Common G code Commands

11. What is the difference between G00 and G01?

G00(Rapid Move) – Moves the tool quickly to a position without cutting.G01(Linear Move) – Moves the tool at a controlled speed while cutting.

12. How do I use G02 and G03 for circular movements?

G02– Moves in a clockwise (CW) arc.G03– Moves in a counterclockwise (CCW) arc.

Example:

G02 X50 Y50 I25 J0 (Clockwise arc with center offset I=25)

G03 X50 Y50 I-25 J0 (Counterclockwise arc)13. What is the purpose of G90 and G91 positioning modes?

G90– Absolute positioning (coordinates based on a fixed zero point).G91– Relative positioning (coordinates based on the last position).

14. What is G28, and how does it return the machine to the home position?

G28 moves the machine to the predefined home position. Example:

G28 X0 Y0 Z0 (Return to home position)15. How do I control the spindle with G code commands?

M03 S1500– Turns the spindle ON clockwise at 1500 RPM.M05– Stops the spindle.

Troubleshooting and Optimization

16. What are common mistakes to avoid when writing G-code?

- Forgetting to set the correct units (G20 for inches, G21 for mm).

- Using the wrong feed rate (F command).

- Not defining the tool path correctly (causing crashes).

17. Why is my CNC machine not following the G code correctly?

Possible reasons include incorrect syntax, missing commands, or machine limits being exceeded.

18. How can I optimize G code for faster and smoother machining?

- Use

G00for rapid moves when cutting isn’t required. - Set the correct feed rate (

Fcommand). - Minimize unnecessary tool movements.

19. What should I do if my CNC machine is moving too slowly or too fast?

Check the feed rate (F value) and spindle speed (S value). Ensure the correct units (mm or inches) are set.

20. How can I simulate G code before running it on a CNC machine?

Use CNC simulators like NC Viewer, CAMotics, or Mach3 to visualize the toolpath before execution.

Advanced G code Topics

21. What are subroutines and macros in G-code?

Subroutines allow you to repeat code sections using M98 and M99, reducing redundancy.

22. How do I use G41 and G42 for cutter compensation?

G41– Left cutter compensation.G42– Right cutter compensation.

These commands adjust toolpaths based on tool diameter.

23. What is G96 and G97 for spindle speed control?

G96– Constant surface speed (used in lathe turning).G97– Cancels G96, setting a fixed spindle speed.

24. How do I program tool changes in G code?

Example:

M06 T2 (Change to tool 2)Some machines also require G43 for tool length offset.

25. Can I use conditional statements in G code programming?

Some controllers support conditional logic using custom macros, but basic G code does not have if-else statements.

G-code for Different Applications

26. Is G code used for 3D printing as well as CNC machining?

Yes, 3D printers use G code, but they include commands specific to extrusion, such as M104 (set extruder temperature).

27. How does G code differ for milling, turning, and laser cutting?

- Milling – Uses

G01,G02,G03for tool movement. - Turning – Uses lathe-specific codes like

G96(constant surface speed). - Laser Cutting – Uses

M3(laser ON) andM5(laser OFF).

28. Can I use G-code for robotic arms and automated systems?

Yes, some industrial robots use modified G code for motion planning.

29. How do I adjust G code for different materials (wood, metal, plastic)?

Modify spindle speed (S), feed rate (F), and depth of cut based on material hardness.

30. What are the differences between Fanuc, Haas, and Siemens G-code formats?

Each brand has unique variations and additional M-codes, though standard G-codes remain similar.

Download BlueBot Controller App and start your journey today!